31/12/2014

30/12/2014

SEISMOLOGY: ADVANCE STUDY IN MODERN CIVIL ENGINEERING

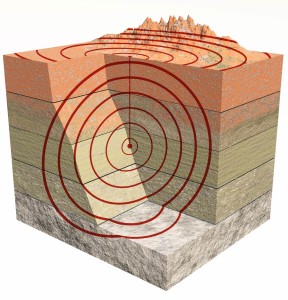

WHAT IS SEISMOLOGY?

It is the branch in which we deals with mechanics, pattern, severeness of Earthquakes. In whole world most of countries have their own seismological department so this thing shows its importance.

Links are given in italic.....

A NOTES ON SEISMOLOGY FROM PURDUE UNIVERSITY..

A NOTES ON SEISMOLOGY FROM MIT...

SOME IMPORTANT TERMS ON SEISMOLOGY

22/12/2014

CARBON FIBER REINFORCED-

Carbon fiber–reinforced polymer, carbon fiber–reinforced plastic or carbon fiber–reinforced thermoplastic (CFRP, CRP, CFRTP or often simply carbon fiber, or even carbon), is an extremely strong and light fiber-reinforced polymer which contains carbon fibers.

CFRPs can be expensive to produce but are commonly used wherever high strength-to-weight ratio and rigidity are required, such as aerospace, automotive and civil engineering, sports goods and an increasing number of other consumer and technical applications.

The binding polymer is often a thermoset resin such as epoxy, but other thermoset or thermoplastic polymers, such as polyester, vinyl ester or nylon, are sometimes used. The composite may contain other fibers, such as aramid e.g. Kevlar, Twaron, aluminium, Ultra-high-molecular-weight polyethylene (UHMWPE) or glass fibers, as well as carbon fiber. The properties of the final CFRP product can also be affected by the type of additives introduced to the binding matrix (the resin). The most frequent additive is silica, but other additives such as rubber and carbon nanotubes can be used. The material is also referred to as graphite-reinforced polymer or graphite fiber-reinforced polymer (GFRP is less common, as it clashes with glass-(fiber)-reinforced polymer). In product advertisements, it is sometimes referred to simply as graphite fiber for short.

FIND MORE DETAIL ABOUT CARBON FIBER CLICK OVER LINK

https://drive.google.com/viewerng/viewer?url=patentimages.storage.googleapis.com/pdfs/US5685902.pdf

Carbon fiber–reinforced polymer, carbon fiber–reinforced plastic or carbon fiber–reinforced thermoplastic (CFRP, CRP, CFRTP or often simply carbon fiber, or even carbon), is an extremely strong and light fiber-reinforced polymer which contains carbon fibers.

CFRPs can be expensive to produce but are commonly used wherever high strength-to-weight ratio and rigidity are required, such as aerospace, automotive and civil engineering, sports goods and an increasing number of other consumer and technical applications.

The binding polymer is often a thermoset resin such as epoxy, but other thermoset or thermoplastic polymers, such as polyester, vinyl ester or nylon, are sometimes used. The composite may contain other fibers, such as aramid e.g. Kevlar, Twaron, aluminium, Ultra-high-molecular-weight polyethylene (UHMWPE) or glass fibers, as well as carbon fiber. The properties of the final CFRP product can also be affected by the type of additives introduced to the binding matrix (the resin). The most frequent additive is silica, but other additives such as rubber and carbon nanotubes can be used. The material is also referred to as graphite-reinforced polymer or graphite fiber-reinforced polymer (GFRP is less common, as it clashes with glass-(fiber)-reinforced polymer). In product advertisements, it is sometimes referred to simply as graphite fiber for short.

FIND MORE DETAIL ABOUT CARBON FIBER CLICK OVER LINK

https://drive.google.com/viewerng/viewer?url=patentimages.storage.googleapis.com/pdfs/US5685902.pdf

FIBER REIN-FORCED CONCERTE

Fiber Reinforced Polymers are by no means new to this world. It is only because of our fascination with petrochemical and non-petrochemical products that these wonderful materials exist. In fact, the polymers can be considered and used in the construction and construction repair. The petrochemical polymers are of low cost and are used more that natural materials. The Fiber Reinforced Polymers research is currently increasing and entails a quickly expanding field due to the vast range of both traditional and special applications in accordance to their characteristics and properties. Fiber Reinforced Polymers are related to the improvement of environmental parameters, consist of important areas of research demonstrating high potential and particularly great interest, as civil construction and concrete repair.

used in concrete shown in image

BOOK LINK TO READ

<a href="http://www.intechopen.com/books/fiber-reinforced-polymers-the-technology-applied-for-concrete-repair" title="Fiber Reinforced Polymers - The Technology Applied for Concrete Repair">Fiber Reinforced Polymers - The Technology Applied for Concrete Repair</a>

A PAPER LINK-

http://www.ce.tuiasi.ro/~bipcons/Archive/120.pdf

Quality improvement by the glass fiber reinforced concrete

http://waset.org/publications/9997631/improving-concrete-properties-with-fibers-addition

used in concrete shown in image

BOOK LINK TO READ

<a href="http://www.intechopen.com/books/fiber-reinforced-polymers-the-technology-applied-for-concrete-repair" title="Fiber Reinforced Polymers - The Technology Applied for Concrete Repair">Fiber Reinforced Polymers - The Technology Applied for Concrete Repair</a>

A PAPER LINK-

http://www.ce.tuiasi.ro/~bipcons/Archive/120.pdf

Quality improvement by the glass fiber reinforced concrete

http://waset.org/publications/9997631/improving-concrete-properties-with-fibers-addition

UPCOMING ERA IN CIVIL ENGINEERING: GEO-POLYMERS links available

WHAT ARE THESE?

Geopolymerconcrete is an innovative material and a real alternative to conventional Portland cement for use in transportation infrastructure, construction and offshore applications. It relies on minimally processed natural materials or industrial byproducts to significantly reduce its carbon footprint, while also being very resistant to many of the durability issues that can plague conventional concretes.

Creating geopolymer cement requires an alumina silicate material, a user-friendly alkaline reagent[2] (sodium or potassium soluble silicates with a molar ratio MR SiO2:M2O>1,65, M being Na or K) and water (See the definition for "user-friendly" reagent below). Room temperature hardening relies on the addition of calcium cations, essentially iron blast furnace slag.

http://cipremier.net/e107_files/downloads/Papers/100/35/100035037.pdf

http://www.fhwa.dot.gov/pavement/concrete/pubs/hif10014/hif10014.pdf

http://old.vscht.cz/sil/pojiva/Poster_1.62_CD.pdf

CLICK OVER THE LINK AND YOU MAY GET YOUR FULL KNOWLEDGE.

PERF

ORMANCE-

Excellent

http://www.ipublishing.co.in/ijcserarticles/twelve/articles/volthree/EIJCSE3137.pdf

BIO FIBERS-

another type of reinforced concrete by suing of pulps of timber etc.

http://elearning.vtu.ac.in/12/enotes/Adv_Conc_Stru/Unit6-MCN.pdf

Geopolymerconcrete is an innovative material and a real alternative to conventional Portland cement for use in transportation infrastructure, construction and offshore applications. It relies on minimally processed natural materials or industrial byproducts to significantly reduce its carbon footprint, while also being very resistant to many of the durability issues that can plague conventional concretes.

Creating geopolymer cement requires an alumina silicate material, a user-friendly alkaline reagent[2] (sodium or potassium soluble silicates with a molar ratio MR SiO2:M2O>1,65, M being Na or K) and water (See the definition for "user-friendly" reagent below). Room temperature hardening relies on the addition of calcium cations, essentially iron blast furnace slag.

http://cipremier.net/e107_files/downloads/Papers/100/35/100035037.pdf

http://www.fhwa.dot.gov/pavement/concrete/pubs/hif10014/hif10014.pdf

http://old.vscht.cz/sil/pojiva/Poster_1.62_CD.pdf

CLICK OVER THE LINK AND YOU MAY GET YOUR FULL KNOWLEDGE.

PERF

ORMANCE-

Excellent

http://www.ipublishing.co.in/ijcserarticles/twelve/articles/volthree/EIJCSE3137.pdf

BIO FIBERS-

another type of reinforced concrete by suing of pulps of timber etc.

http://elearning.vtu.ac.in/12/enotes/Adv_Conc_Stru/Unit6-MCN.pdf

20/12/2014

OLD TIME CIVIL ENGINEERING NOW WHAT ARE THESE

FAMOUS CULTURAL MONUMENTS OLD TIME BY THE CIVIL ENGINEERING

A monument is a type of structure either explicitly created to commemorate a person or important event or which has become important to a social group as a part of their remembrance of historic times or cultural heritage, or simply as an example of historic architecture.

Everybody knows the most famous cultural monuments in the world, Anyhow, here you will find some if not all most famous monuments around the world as well as some not everybody knows. Each of these cultural icons is a symbol with various meanings, it may represent an epoch, an area, a belief, a culture, a country or a city. Below is a top 10 list of most Famous Cultural monuments in the world.

Top 10 Most Famous Cultural Monuments Around the World

1. The Kaaba (Masjid al-Haram)

Kaaba (Allah Almighty's House) in Makka, Famous Cultural monuments

World’s Most Famous Cultural Monuments

The Kaaba (Masjid al-Haram) is a cuboid-shaped building in Mecca, Saudi Arabia, and is the most sacred site in Islam, oldest and top the most Famous Cultural monuments in the world. The Quran states that the Kaaba was constructed by Abraham (Ibrahim in Arabic), and his son Ishmael (Ismaeel in Arabic), after the latter had settled in Arabia. The building has a mosque built around it, the Masjid al-Haram. All Muslims around the world face the Kaaba during prayers, no matter where they are. This is called facing the Qiblah.

One of the Five Pillars of Islam requires every Muslim to perform the Hajj pilgrimage at least once in his or her lifetime if able to do so. Multiple parts of the Hajj require pilgrims to walk seven times around the Kaaba in a counter-clockwise direction (as viewed from above). This circumambulation, the Tawaf, is also performed by pilgrims during the Umrah (lesser pilgrimage). However, the most dramatic times are during the Hajj, when about 6 million pilgrims gather to circle the building on the same day.

2. The Taj Mahal

Famous Cultural Monuments

Taj Mahal “crown of palaces”, world heritage site is a white marble mausoleum located in Agra, Uttar Pradesh, India, seen from the banks of Yamuna river, with Mihman Khana or assembly hall (left) and Taj Mahal mosque (right), the two almost identical buildings on either side. It was built by Mughal emperor Shah Jahan in memory of his third wife, Mumtaz Mahal. The Taj Mahal is widely recognized as “the jewel of Muslim art in India and one of the universally admired masterpieces of the world’s heritage.It coveres area about 221 hectare (552 Acres) which include 38 hectare taj mahal and 183 hectare taj protected forest are. This world’s most Famous Cultural Monuments is also one of the wonders of the world.

3. The Egyptian pyramids are ancient pyramid-shaped masonry structures located in Egypt.

Giza Pyramid Famous Cultural Monuments

Famous Cultural Monuments

There are 138 pyramids discovered in Egypt as of 2008. Most were built as tombs for the country’s Pharaohs and their consorts during the Old and Middle Kingdom periods. These are some of oldest Famous Cultural Monuments.

The earliest known Egyptian pyramids are found at Saqqara, northwest of Memphis. The earliest among these is the Pyramid of Djoser (constructed 2630 BCE–2611 BCE) which was built during the third dynasty. This pyramid and its surrounding complex were designed by the architect Imhotep, and are generally considered to be the world’s oldest monumental structures constructed of dressed masonry.

4. The Great Wall of China

The Great Wall of China is a series of fortifications made of stone, brick, tamped earth, wood, and other materials, generally built along an east-to-west line across the historical northern borders of China in part to protect the Chinese Empire or its prototypical states against intrusions by various nomadic groups or military incursions by various warlike peoples or forces. Several walls were being built as early as the 7th century BC; these, later joined together and made bigger, stronger, and unified are now collectively referred to as the Great Wall. Especially famous is the wall built between 220–206 BC by the first Emperor of China, Qin Shi Huang. Little of that wall remains. Since then, the Great Wall has on and off been rebuilt, maintained, enhanced; the majority of the existing wall was reconstructed during the Ming Dynasty. One of the most Famous Cultural Monuments and Wonders of the world.

5. Angkor Thom (Big Angkor)

South gate, Famous Cultural Monuments

Angkor Thom is a 3km2 walled and moated royal city and was the last capital of the Angkorian empire. After Jayavarman VII recaptured the Angkorian capital from the Cham invaders in 1181, he began a massive building campaign across the empire, constructing Angkor Thom as his new capital city. He began with existing structures such as Baphuon and Phimeanakas and built a grand enclosed city around them, adding the outer wall/moat and some of Angkor’s greatest temples including his state-temple, Bayon, set at the center of the city. There are five entrances (gates) to the city, one for each cardinal point, and the victory gate leading to the Royal Palace area. Each gate is crowned with 4 giant faces. The South Gate is often the first stop on a tour.

6. The Acropolis hill

Acropolis of Athens

The Acropolis hill, so called the “Sacred Rock” of Athens, is the most important site of the city and constitutes one of the most recognizable monuments of the world. It is the most significant reference point of ancient Greek culture, as well as the symbol of the city of Athens itself as it represent the apogee of artistic development in the 5th century BC. During Perikles’ Golden Age, ancient Greek civilization was represented in an ideal way on the hill and some of the architectural masterpieces of the period were erected on its ground.

7. The National Chiang Kai-shek Memorial Hall

Chiang Kai-shek Memorial Hall

The National Chiang Kai-shek Memorial Hall is a famous monument, landmark and tourist attraction erected in memory of Generalissimo Chiang Kai-shek, former President of the Republic of China. It is located in Taipei, Republic of China (ROC).

The monument, surrounded by a park, stands at the east end of Memorial Hall Square. The structure is framed on the north and south by the National Theater and National Concert Hall.

8. The Potala Palace

The Potala Palace from the south-east

Famous Cultural Monuments

The Potala Palace is located in Lhasa, Tibet Autonomous Region, China. It is named after Mount Potalaka, the mythical abode of Chenresig or Avalokitesvara. The Potala Palace was the chief residence of the Dalai Lama until the 14th Dalai Lama fled to Dharamsala, India, during the 1959 Tibetan uprising.

Lozang Gyatso, the Great Fifth Dalai Lama, started the construction of the Potala Palace in 1645 after one of his spiritual advisers, Konchog Chophel (d. 1646), pointed out that the site was ideal as a seat of government, situated as it is between Drepung and Sera monasteries and the old city of Lhasa. It may overlay the remains of an earlier fortress, called the White or Red Palace, on the site built by Songtsen Gampo in 637. Today, the Potala Palace is a museum.

9. Liberty Enlightening the World

Statue of Liberty, New York City, USA

Famous Cultural Monuments

The Statue of Liberty Enlightening the World was a gift of friendship from the people of France to the people of the United States and is a universal symbol of freedom and democracy. The Statue of Liberty was dedicated on October 28, 1886, designated as a National Monument in 1924 and restored for her centennial on July 4, 1986.

10. The Sultan Ahmed Mosque

Blue Mosque

Most Famous Cultural Monuments

The Sultan Ahmed Mosque is an historical mosque in Istanbul, the largest city in Turkey and the capital of the Ottoman Empire (from 1453 to 1923). The mosque is popularly known as the Blue Mosque for the blue tiles adorning the walls of its interior.

It was built from 1609 to 1616, during the rule of Ahmed I. Like many other mosques, it also comprises a tomb of the founder, a madrasah and a hospice. While still used as a mosque, the Sultan Ahmed Mosque has also become a popular tourist attraction.

A monument is a type of structure either explicitly created to commemorate a person or important event or which has become important to a social group as a part of their remembrance of historic times or cultural heritage, or simply as an example of historic architecture.

Everybody knows the most famous cultural monuments in the world, Anyhow, here you will find some if not all most famous monuments around the world as well as some not everybody knows. Each of these cultural icons is a symbol with various meanings, it may represent an epoch, an area, a belief, a culture, a country or a city. Below is a top 10 list of most Famous Cultural monuments in the world.

Top 10 Most Famous Cultural Monuments Around the World

1. The Kaaba (Masjid al-Haram)

Kaaba (Allah Almighty's House) in Makka, Famous Cultural monuments

World’s Most Famous Cultural Monuments

The Kaaba (Masjid al-Haram) is a cuboid-shaped building in Mecca, Saudi Arabia, and is the most sacred site in Islam, oldest and top the most Famous Cultural monuments in the world. The Quran states that the Kaaba was constructed by Abraham (Ibrahim in Arabic), and his son Ishmael (Ismaeel in Arabic), after the latter had settled in Arabia. The building has a mosque built around it, the Masjid al-Haram. All Muslims around the world face the Kaaba during prayers, no matter where they are. This is called facing the Qiblah.

One of the Five Pillars of Islam requires every Muslim to perform the Hajj pilgrimage at least once in his or her lifetime if able to do so. Multiple parts of the Hajj require pilgrims to walk seven times around the Kaaba in a counter-clockwise direction (as viewed from above). This circumambulation, the Tawaf, is also performed by pilgrims during the Umrah (lesser pilgrimage). However, the most dramatic times are during the Hajj, when about 6 million pilgrims gather to circle the building on the same day.

2. The Taj Mahal

Famous Cultural Monuments

Taj Mahal “crown of palaces”, world heritage site is a white marble mausoleum located in Agra, Uttar Pradesh, India, seen from the banks of Yamuna river, with Mihman Khana or assembly hall (left) and Taj Mahal mosque (right), the two almost identical buildings on either side. It was built by Mughal emperor Shah Jahan in memory of his third wife, Mumtaz Mahal. The Taj Mahal is widely recognized as “the jewel of Muslim art in India and one of the universally admired masterpieces of the world’s heritage.It coveres area about 221 hectare (552 Acres) which include 38 hectare taj mahal and 183 hectare taj protected forest are. This world’s most Famous Cultural Monuments is also one of the wonders of the world.

3. The Egyptian pyramids are ancient pyramid-shaped masonry structures located in Egypt.

Giza Pyramid Famous Cultural Monuments

Famous Cultural Monuments

There are 138 pyramids discovered in Egypt as of 2008. Most were built as tombs for the country’s Pharaohs and their consorts during the Old and Middle Kingdom periods. These are some of oldest Famous Cultural Monuments.

The earliest known Egyptian pyramids are found at Saqqara, northwest of Memphis. The earliest among these is the Pyramid of Djoser (constructed 2630 BCE–2611 BCE) which was built during the third dynasty. This pyramid and its surrounding complex were designed by the architect Imhotep, and are generally considered to be the world’s oldest monumental structures constructed of dressed masonry.

4. The Great Wall of China

The Great Wall of China is a series of fortifications made of stone, brick, tamped earth, wood, and other materials, generally built along an east-to-west line across the historical northern borders of China in part to protect the Chinese Empire or its prototypical states against intrusions by various nomadic groups or military incursions by various warlike peoples or forces. Several walls were being built as early as the 7th century BC; these, later joined together and made bigger, stronger, and unified are now collectively referred to as the Great Wall. Especially famous is the wall built between 220–206 BC by the first Emperor of China, Qin Shi Huang. Little of that wall remains. Since then, the Great Wall has on and off been rebuilt, maintained, enhanced; the majority of the existing wall was reconstructed during the Ming Dynasty. One of the most Famous Cultural Monuments and Wonders of the world.

5. Angkor Thom (Big Angkor)

South gate, Famous Cultural Monuments

Angkor Thom is a 3km2 walled and moated royal city and was the last capital of the Angkorian empire. After Jayavarman VII recaptured the Angkorian capital from the Cham invaders in 1181, he began a massive building campaign across the empire, constructing Angkor Thom as his new capital city. He began with existing structures such as Baphuon and Phimeanakas and built a grand enclosed city around them, adding the outer wall/moat and some of Angkor’s greatest temples including his state-temple, Bayon, set at the center of the city. There are five entrances (gates) to the city, one for each cardinal point, and the victory gate leading to the Royal Palace area. Each gate is crowned with 4 giant faces. The South Gate is often the first stop on a tour.

6. The Acropolis hill

Acropolis of Athens

The Acropolis hill, so called the “Sacred Rock” of Athens, is the most important site of the city and constitutes one of the most recognizable monuments of the world. It is the most significant reference point of ancient Greek culture, as well as the symbol of the city of Athens itself as it represent the apogee of artistic development in the 5th century BC. During Perikles’ Golden Age, ancient Greek civilization was represented in an ideal way on the hill and some of the architectural masterpieces of the period were erected on its ground.

7. The National Chiang Kai-shek Memorial Hall

Chiang Kai-shek Memorial Hall

The National Chiang Kai-shek Memorial Hall is a famous monument, landmark and tourist attraction erected in memory of Generalissimo Chiang Kai-shek, former President of the Republic of China. It is located in Taipei, Republic of China (ROC).

The monument, surrounded by a park, stands at the east end of Memorial Hall Square. The structure is framed on the north and south by the National Theater and National Concert Hall.

8. The Potala Palace

The Potala Palace from the south-east

Famous Cultural Monuments

The Potala Palace is located in Lhasa, Tibet Autonomous Region, China. It is named after Mount Potalaka, the mythical abode of Chenresig or Avalokitesvara. The Potala Palace was the chief residence of the Dalai Lama until the 14th Dalai Lama fled to Dharamsala, India, during the 1959 Tibetan uprising.

Lozang Gyatso, the Great Fifth Dalai Lama, started the construction of the Potala Palace in 1645 after one of his spiritual advisers, Konchog Chophel (d. 1646), pointed out that the site was ideal as a seat of government, situated as it is between Drepung and Sera monasteries and the old city of Lhasa. It may overlay the remains of an earlier fortress, called the White or Red Palace, on the site built by Songtsen Gampo in 637. Today, the Potala Palace is a museum.

9. Liberty Enlightening the World

Statue of Liberty, New York City, USA

Famous Cultural Monuments

The Statue of Liberty Enlightening the World was a gift of friendship from the people of France to the people of the United States and is a universal symbol of freedom and democracy. The Statue of Liberty was dedicated on October 28, 1886, designated as a National Monument in 1924 and restored for her centennial on July 4, 1986.

10. The Sultan Ahmed Mosque

Blue Mosque

Most Famous Cultural Monuments

The Sultan Ahmed Mosque is an historical mosque in Istanbul, the largest city in Turkey and the capital of the Ottoman Empire (from 1453 to 1923). The mosque is popularly known as the Blue Mosque for the blue tiles adorning the walls of its interior.

It was built from 1609 to 1616, during the rule of Ahmed I. Like many other mosques, it also comprises a tomb of the founder, a madrasah and a hospice. While still used as a mosque, the Sultan Ahmed Mosque has also become a popular tourist attraction.

15/12/2014

TREMENDOUS WORK IN CIVIL ENGINEERING: Bullet Proof Cement

Engineers Developing Bullet Proof Vests From Cement

The new vests will combine super-strong cement with recycled carbon fibre materials to make a material tough enough to withstand most types of bullets.

The cement vest project, still at the early research stage, is being carried out the School of Civil Engineering at the University.

Dr Philip Purnell, who is leading the team, said: "By using cement instead of alumina we are confident we can deliver a cost-effective level of protection for many people at risk. It should be good enough for people like security guards, reporters and aid workers who are worried about the odd pot shot being taken at them.

"The fact is many of the armored vests sold today are over-engineered for the threats they face. Cement based body armour would not only create a whole new market but it would also take some of the pressure off the demand for hi-spec alumina models so that people like soldiers, who really need this kit, can get it."

Currently available hi-spec body armour is constructed with alumina plates - the raw material used to make aluminium - which is heated to 1600 degrees Celsius for up to two weeks in a process called 'sintering' in order to make them ultra hard.

Enhanced combat body armour (ECBA) as supplied to UK troops uses sintered alumina plates. In the past UK and US soldiers serving in Iraq and Afghanistan have faced shortages of ECBA as production has struggled to keep up with soaring global demand.

Cement vests are just one of a range of novel uses for the 2000 year old material that the Leeds engineers are investigating in a three year project called'Cementing the future'. Other ideas include cement based pump-less fridges, a new type of catalytic converter, and improved bone replacements.

Dr Purnell is actively seeking other researchers, engineers, scientists, designers or even sculptors and artists who also have ideas for new uses for cement.

13/12/2014

MAGIC IN CIVIL ENGINEER!! Water-less Concrete: In Moon, House will made by these!!!!

WONDERFUL Water-less Concrete

Traditional concrete comprises a binder — cement and water — mixed with aggregates. While some parts of the Moon may have water, that resource may be more valuable for astronaut’s consumption rather than building structures.

His research shows that those astronauts can turn to a new type of water-less concrete that uses lunar soil as the aggregate and sulfur as a binding agent.

Toutanji, who is also chair of the civil and environmental engineering department at U A Huntsville, has spent years studying the characteristics of cementitious materials, said he anticipates concrete to play a major role in constructing facilities on the lunar surface to survive the harsh environment on the Moon’s surface.

NASA is searching for a means to use resources that are available from the surface of the moon, according to Toutanji.

“The difficulty of transporting materials from Earth will place a premium on resourcefulness and ingenuity,” he said.

Toutanji was co-author of the article along with Dr. Richard N. Grugel, a geological engineer at NASA’s Marshall Space Flight Center.

HOW A DAM CAN BE BUILT?? ITS DESIGN AND PROCEDURE

PROCEDURE TO DESIGN A DAM-

Aggregate Production - The acceptability of natural aggregates is judged upon the physical and chemical properties of the material and the accessibility, proximity to the site and economic workability of the deposit.

Concrete Handling, Placing and Consolidation - The procedure to be adopted for moving concrete from the mixers on to the dam will be governed by site conditions. The problem is to transport it to the dam with the least possible segregation or change in its consistency so it may be compacted uniformly into the dam without unreasonable effort. The cableway is probably the simplest arrangement. The tilting mixers will feed the buckets; these are then moved to a pick up point under the cableway, transported smoothly to the block and emptied quickly through an air operated gate.

Three Tower Cableway

The use of a belt conveyor has also been considered, but problems occur in keeping the belt temperature stable in warm weather and also in windy conditions. The conveyors are usually covered and cold air is blown over the concrete to lower its placing temperature.

The placing of a low-slump concrete, four layers in 2.3m lift

Tractor mounted vibrators at Emosson Dam, Switzerland

Proper consolidation of low-slump concrete is laborious and requires continuous supervision. The most efficient compactor is usually the two man hand-held high-speed vibrator.

Formwork - Probably the most widely used lift is 1.5m, however, on large dams a height of 2.3-3.0m is frequently used. With the larger lifts there are fewer movements of forms and fewer horizontal lift surfaces to be cleaned. The high-lift formwork is unique and expensive with less prospect for re-use, heavier equipment is required for lifting the forms and the heat problems and risks of cracking in the concrete are accentuated. Modern steel formwork is of cantilever design, see figure. Where possible the use of slip forms will expedite the work and lower the costs. At some locations it may be expedient to use precast concrete slabs for formwork with set-retarding agent on the inner surface.

Built in items - The installation of built in items is always a major source of delay on construction. Advance planning is required with close attention to detail. The complication of installation of reinforcement, prestressing, gate hinges, drainage wells and gate wells are common on spillways. There has been a tendency to use precast concrete units for galleries to save time, however this prevents the inspection of the concrete in the interior of the dam. The simplest method of forming galleries is vertical formwork extending the full height of a lift. When this is removed, precast concrete beams or slabs can be laid over the opening and concreted into the next lift. Reinforcement is usually required above and below rectangular galleries and this is best installed as prefabricated units.

Cooling of Concrete - The method of cooling concrete during the first few days after placing can be of the utmost importance if cracking is to avoided. It is essential to give attention to both internal and external factors that may induce cracking;

THE SITES FOR DESIGN OF DAMS

1) http://nptel.ac.in/courses/105105110/pdf/m4l07.pdf

2) https://npdp.stanford.edu/sites/default/files/other_materials/the_design_and_construction_of_dams.pdf

3) http://nptel.ac.in/courses/105105110/pdf/m4l06.pdf

Aggregate Production - The acceptability of natural aggregates is judged upon the physical and chemical properties of the material and the accessibility, proximity to the site and economic workability of the deposit.

Concrete Handling, Placing and Consolidation - The procedure to be adopted for moving concrete from the mixers on to the dam will be governed by site conditions. The problem is to transport it to the dam with the least possible segregation or change in its consistency so it may be compacted uniformly into the dam without unreasonable effort. The cableway is probably the simplest arrangement. The tilting mixers will feed the buckets; these are then moved to a pick up point under the cableway, transported smoothly to the block and emptied quickly through an air operated gate.

The use of a belt conveyor has also been considered, but problems occur in keeping the belt temperature stable in warm weather and also in windy conditions. The conveyors are usually covered and cold air is blown over the concrete to lower its placing temperature.

Proper consolidation of low-slump concrete is laborious and requires continuous supervision. The most efficient compactor is usually the two man hand-held high-speed vibrator.

Formwork - Probably the most widely used lift is 1.5m, however, on large dams a height of 2.3-3.0m is frequently used. With the larger lifts there are fewer movements of forms and fewer horizontal lift surfaces to be cleaned. The high-lift formwork is unique and expensive with less prospect for re-use, heavier equipment is required for lifting the forms and the heat problems and risks of cracking in the concrete are accentuated. Modern steel formwork is of cantilever design, see figure. Where possible the use of slip forms will expedite the work and lower the costs. At some locations it may be expedient to use precast concrete slabs for formwork with set-retarding agent on the inner surface.

Cooling of Concrete - The method of cooling concrete during the first few days after placing can be of the utmost importance if cracking is to avoided. It is essential to give attention to both internal and external factors that may induce cracking;

- Temperature rise, which will depend upon the heat of hydration of the cement, the quantity of cement per cubic metre, the concrete placing temperature and the rate of construction;

- Heat dissipation, which will depend upon the conditions of exposure - including the temperature of the underlying concrete and the thermal diffusivity of the concrete. If it is considered necessary to heat the underlying concrete the rate of rise of its temperature should not exceed 2° Celsius per day;

- The effects of restraint from a cold surface, i.e. rock or concrete say 14 days old, it will depend upon the temperature gradient which can be reduced by placing concrete in half lifts for a predetermined height, say 3m above the cold surface;

- The arrangement of cooling pipes - at 0.25 and 0.75 of the height of the lift may be more efficient than on the top of the old lift and at mid-height of the new lift. The horizontal spacing will depend upon the rate of heat removal required and the temperature of the cooling water (i.e. river water of varying temperature or refrigerated water);

- The local weather conditions - humidity, temperature and wind.

- Is it permissible to design for tensile stress in the concrete?

- Will arching of the dam result in overall economy?

- Are longitudinal contraction joints necessary in large gravity dams?

- Can the transverse contraction joints be omiited, located at wider spacing etc?

- What clean up is necessary on horizontal construction joints?

- Should the height of lift be specified by the designer?

- Should the cement content of the concrete be specified or only the properties required in the concrete?

- Can the dams of intricate shape be justified?

- Should ancillary works be separated from the dam to minimise interference with a continuous or cyclic process of dam building?

- What is the optimum layout and design for galleries?

THE SITES FOR DESIGN OF DAMS

1) http://nptel.ac.in/courses/105105110/pdf/m4l07.pdf

2) https://npdp.stanford.edu/sites/default/files/other_materials/the_design_and_construction_of_dams.pdf

3) http://nptel.ac.in/courses/105105110/pdf/m4l06.pdf

12/12/2014

DAM: WHAT IS ITS IMPORTANCE ALL YOU KNOW

A dam is a barrier that impounds water or underground streams. The reservoirs created by dams not only suppress floods but provide water for various needs to include irrigation, human consumption, industrial use, aquaculture and navigability. Hydro power is often used in conjunction with dams to generate electricity. A dam can also be used to collect water or for storage of water which can be evenly distributed between locations. Dams generally serve the primary purpose of retaining water, while other structures such as floodgates or levees (also known as dikes) are used to manage or prevent water flow into specific land regions.Early dam building took place in Mesopotamia and the Middle East. Dams were used to control the water level, for Mesopotamia's weather affected the Tigris and Euphrates rivers, and could be quite unpredictable.

The earliest known dam is the Jawa Dam in Jordan, 100 kilometres (62 mi) northeast of the capital Amman. This gravity dam featured an originally 9 m (30 ft) high and 1 m (3 ft 3 in) wide stone wall, supported by a 50 m (160 ft) wide earth rampart. The structure is dated to 3000 BC.

The earliest known dam is the Jawa Dam in Jordan, 100 kilometres (62 mi) northeast of the capital Amman. This gravity dam featured an originally 9 m (30 ft) high and 1 m (3 ft 3 in) wide stone wall, supported by a 50 m (160 ft) wide earth rampart. The structure is dated to 3000 BC.

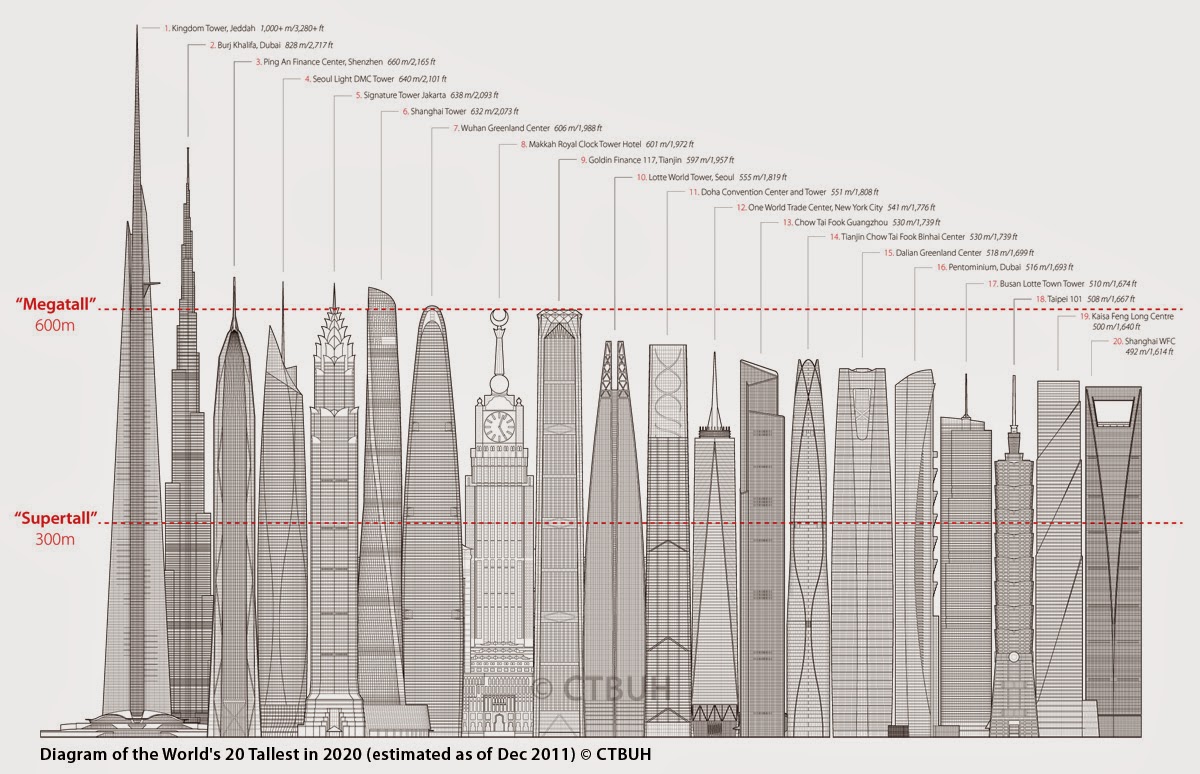

The Tallest 20 in 2020: Entering the Era of the Megatall

As we started the 21st century, just 11 short years ago, the Petronas Towers held the title of “The World’s Tallest” at 452 meters (1,483 feet) in height. Taipei 101 took the title in 2004, at 508 meters (1,667 feet).Then, at the end of the decade, the Burj Khalifa set new standards at 828 meters (2,717 feet) – over half a mile high. Now, with work set to start on-site in January 2012 for Jeddah’s 1,000+ meter Kingdom Tower

, we can expect that in a mere two decades (2000–2020) the height of the “World’s Tallest Building” will have more than doubled.

THE KINGDOM TOWER

The Kingdom Tower will have a height of at least 1000 meters, and thus it will be 173 meters higher than Burj Khalifa.

The Tower is designed by Adrian Smith and Gordon Gill Architecture. Adrian Smith was the architect of the Burj Khalifa in Dubai, the current highest building in the world.

It is estimated that the construction of the Kingdom Tower in Jeddah will last 63 months, although it may take longer for the project to complete. The Kingdom Tower is currently the highest building that was approved for construction. The tower will be served by 56 elevators. The estimated cost of the building is 4.6 billion SR (about 1.2 billion USD) as of August 2011 although this figure is subject to change. The tower will house a hotel; offices, apartments as well as it will be the tallest observation spot.

, we can expect that in a mere two decades (2000–2020) the height of the “World’s Tallest Building” will have more than doubled.

THE KINGDOM TOWER

The Kingdom Tower will have a height of at least 1000 meters, and thus it will be 173 meters higher than Burj Khalifa.

The Tower is designed by Adrian Smith and Gordon Gill Architecture. Adrian Smith was the architect of the Burj Khalifa in Dubai, the current highest building in the world.

It is estimated that the construction of the Kingdom Tower in Jeddah will last 63 months, although it may take longer for the project to complete. The Kingdom Tower is currently the highest building that was approved for construction. The tower will be served by 56 elevators. The estimated cost of the building is 4.6 billion SR (about 1.2 billion USD) as of August 2011 although this figure is subject to change. The tower will house a hotel; offices, apartments as well as it will be the tallest observation spot.

HEY GREAT CIVIL ENGINEERS!!! PROUD ON YOURSELF! SUEZ A ROUTE WHICH MEANS ITSELF

MY DEAR FRIENDS,

CLIK OVER THE LINK AND GET THE HISTORICAL, STRAGICAL IMPORTANCE OF SUEZ CANAL.. PLEASE CHECK FOR ONE TIME...

web.mst.edu/~rogersda/umrcourses/ge342/Suez%20Canal.pdf

CLIK OVER THE LINK AND GET THE HISTORICAL, STRAGICAL IMPORTANCE OF SUEZ CANAL.. PLEASE CHECK FOR ONE TIME...

web.mst.edu/~rogersda/umrcourses/ge342/Suez%20Canal.pdf

11/12/2014

A GREAT ACHIEVEMENT IN ENGINEERING HISTORY PANAMA CANAL

Building the Panama Canal, 1903–1914

President Theodore Roosevelt oversaw the realization of a long-term United States goal—a trans-isthmian canal. Throughout the 1800s, American and British leaders and businessmen wanted to ship goods quickly and cheaply between the Atlantic and Pacific coasts.

Roosevelt on a digging machine during construction of the Panama

Canal, circa 1908. (Library of Congress, Prints and Photographs Division)

Roosevelt on a digging machine during construction of the Panama

Canal, circa 1908. (Library of Congress, Prints and Photographs Division)

To that end, in 1850 the United States and Great Britain negotiated the

Clayton-Bulwer Treaty to reign in rivalry over a proposed canal through the

Central American Republic of Nicaragua. The Anglo-American canal, however, never

went beyond the planning stages. French attempts to build a canal through Panama

(province of Colombia) advanced further. Led by Ferdinand de Lesseps—the builder

of the Suez Canal in Egypt—the French began excavating in 1880. Malaria, yellow

fever, and other tropical diseases conspired against the de Lesseps campaign and

after 9 years and a loss of approximately 20,000 lives, the French attempt went

bankrupt. In spite of such setbacks, American interest in a canal continued

unabated. The Hay-Pauncefote Treaty of 1901 abrogated the earlier Clayton-Bulwer

Treaty and licensed the United States to build and manage its own canal.

Following heated debate over the location of the proposed canal, on June 19,

1902, the U.S. Senate voted in favor of building the canal through Panama.

Within 6 months, Secretary of State John Hay signed a

treaty with Colombian Foreign Minister Tomás Herrán to build the new canal. The

financial terms were unacceptable to Colombia’s congress, and it rejected the

offer.

President Roosevelt responded by dispatching U.S. warships to Panama City (on the Pacific) and Colón (on the Atlantic) in support of Panamanian independence. Colombian troops were unable to negotiate the jungles of the Darien Strait and Panama declared independence on November 3, 1903. The newly declared Republic of Panama immediately named Philippe Bunau-Varilla (a French engineer who had been involved in the earlier de Lesseps canal attempt) as Envoy Extraordinary and Minister Plenipotentiary. In his new role, Bunau-Varilla negotiated the Hay-Bunau-Varilla Treaty of 1903, which provided the United States with a 10-mile wide strip of land for the canal, a one-time $10 million payment to Panama, and an annual annuity of $250,000. The United States also agreed to guarantee the independence of Panama. Completed in 1914, the Panama Canal symbolized U.S. technological prowess and economic power. Although U.S. control of the canal eventually became an irritant to U.S.-Panamanian relations, at the time it was heralded as a major foreign policy achievement.

http://natgeotv.com.au/videos/big-bigger-biggest/canal-construction-78FDFEEB.aspx

President Theodore Roosevelt oversaw the realization of a long-term United States goal—a trans-isthmian canal. Throughout the 1800s, American and British leaders and businessmen wanted to ship goods quickly and cheaply between the Atlantic and Pacific coasts.

Roosevelt on a digging machine during construction of the Panama

Canal, circa 1908. (Library of Congress, Prints and Photographs Division)

Roosevelt on a digging machine during construction of the Panama

Canal, circa 1908. (Library of Congress, Prints and Photographs Division)

President Roosevelt responded by dispatching U.S. warships to Panama City (on the Pacific) and Colón (on the Atlantic) in support of Panamanian independence. Colombian troops were unable to negotiate the jungles of the Darien Strait and Panama declared independence on November 3, 1903. The newly declared Republic of Panama immediately named Philippe Bunau-Varilla (a French engineer who had been involved in the earlier de Lesseps canal attempt) as Envoy Extraordinary and Minister Plenipotentiary. In his new role, Bunau-Varilla negotiated the Hay-Bunau-Varilla Treaty of 1903, which provided the United States with a 10-mile wide strip of land for the canal, a one-time $10 million payment to Panama, and an annual annuity of $250,000. The United States also agreed to guarantee the independence of Panama. Completed in 1914, the Panama Canal symbolized U.S. technological prowess and economic power. Although U.S. control of the canal eventually became an irritant to U.S.-Panamanian relations, at the time it was heralded as a major foreign policy achievement.

http://natgeotv.com.au/videos/big-bigger-biggest/canal-construction-78FDFEEB.aspx

WHAT A RAILWAY TRACK CAN DO FOR ITS COUNTRY? READ AND KNOW.TRANS-SIBERIAN RAILWAY TRACK

The Trans-Siberian Railway (TSR, Russian: Транссиби́рская магистра́ль, tr. Transsibirskaya Magistral) is a network of railways connecting Moscow with the Russian Far East and the Sea of Japan With a length of 9,289 km (5,772 mi), it is the longest railway line in the world. There are connecting branch lines into Mongolia, China and North Korea. It has connected Moscow with Vladivostok since 1916, and is still being expanded.

It was built from 1891 to 1916 under the supervision of Russian government ministers who were personally appointed by Tsar Alexander III and by his son, Tsar Nicholas II.

Route description

The Trans-Siberian Railway is often associated with the main transcontinental Russian line that connects hundreds of large and small cities of the European and Asian parts of Russia. At 9,259 kilometres (5,753 miles),[3] spanning a record seven time zones and taking eight days to complete the journey, it is the third-longest single continuous service in the world, after the Moscow–Pyongyang 10,267 kilometres (6,380 mi)[4] and the Kiev–Vladivostok 11,085 kilometres (6,888 mi)[5] services, both of which also follow the Trans-Siberian for much of their routes.

The main route of the Trans-Siberian Railway begins in Moscow at Yaroslavsky Vokzal, runs throughYaroslavl, Chelyabinsk, Omsk, Novosibirsk, Irkutsk, Ulan-Ude, Chita and Khabarovsk to Vladivostok via southern Siberia.

A second primary route is the Trans-Manchurian, which coincides with the Trans-Siberian east of Chita as far as Tarskaya (a stop 12 km (7 mi) east of Karymskoye, in Chita Oblast), about 1,000 km (621 mi) east ofLake Baikal. From Tarskaya the Trans-Manchurian heads southeast, via Harbin and Mudanjiang in China'sNortheastern Provinces (from where a connection to Beijing is used by one of the Moscow–Beijing trains), joining with the main route in Ussuriysk just north of Vladivostok. This is the shortest and the oldest railway route to Vladivostok. Some trains split at Shenyang, China, with a portion of the service continuing to Pyongyang, North Korea.

The third primary route is the Trans-Mongolian Railway, which coincides with the Trans-Siberian as far asUlan-Ude on Lake Baikal's eastern shore. From Ulan-Ude the Trans-Mongolian heads south to Ulaan-Baatar before making its way southeast to Beijing.

In 1991, a fourth route running further to the north was finally completed, after more than five decades of sporadic work. Known as the Baikal Amur Mainline (BAM), this recent extension departs from the Trans-Siberian line at Taishet several hundred miles west of Lake Baikal and passes the lake at its northernmost extremity. It crosses the Amur River at Komsomolsk-na-Amure (north of Khabarovsk), and reaches theTatar Strait of the Sea of Japan at Sovetskaya Gavan.

On 13 October 2011 a train from Khasan made its inaugural run to Rajin in North Korea.[6]

The main route of the Trans-Siberian Railway begins in Moscow at Yaroslavsky Vokzal, runs throughYaroslavl, Chelyabinsk, Omsk, Novosibirsk, Irkutsk, Ulan-Ude, Chita and Khabarovsk to Vladivostok via southern Siberia.

A second primary route is the Trans-Manchurian, which coincides with the Trans-Siberian east of Chita as far as Tarskaya (a stop 12 km (7 mi) east of Karymskoye, in Chita Oblast), about 1,000 km (621 mi) east ofLake Baikal. From Tarskaya the Trans-Manchurian heads southeast, via Harbin and Mudanjiang in China'sNortheastern Provinces (from where a connection to Beijing is used by one of the Moscow–Beijing trains), joining with the main route in Ussuriysk just north of Vladivostok. This is the shortest and the oldest railway route to Vladivostok. Some trains split at Shenyang, China, with a portion of the service continuing to Pyongyang, North Korea.

The third primary route is the Trans-Mongolian Railway, which coincides with the Trans-Siberian as far asUlan-Ude on Lake Baikal's eastern shore. From Ulan-Ude the Trans-Mongolian heads south to Ulaan-Baatar before making its way southeast to Beijing.

In 1991, a fourth route running further to the north was finally completed, after more than five decades of sporadic work. Known as the Baikal Amur Mainline (BAM), this recent extension departs from the Trans-Siberian line at Taishet several hundred miles west of Lake Baikal and passes the lake at its northernmost extremity. It crosses the Amur River at Komsomolsk-na-Amure (north of Khabarovsk), and reaches theTatar Strait of the Sea of Japan at Sovetskaya Gavan.

On 13 October 2011 a train from Khasan made its inaugural run to Rajin in North Korea.[6]

History

Demand and design

In the late 19th century, the development of Siberia was hampered by poor transport links within the region, as well as with the rest of the country. Aside from the Great Siberian Route, good roads suitable for wheeled transport were few and far between. For about five months of the year, rivers were the main means of transport. During the cold half of the year, cargo and passengers travelled by horse-drawn sleds over the winter roads, many of which were the same rivers, now ice-covered.

The first steamboat on the River Ob, Nikita Myasnikov's Osnova, was launched in 1844. But early beginnings were difficult, and it was not until 1857 that steamboat shipping started developing on the Ob system in a serious way. Steamboats started operating on the Yenisei in 1863, on the Lena and Amur in the 1870s.

While the comparative flatness of Western Siberia was at least fairly well served by the gigantic Ob–Irtysh–Tobol–Chulym river system, the mighty rivers of Eastern Siberia—the Yenisei, the upper course of the Angara River (the Angara below . was not easily navigable because of the rapids), and the Lena — were mostly navigable only in the north-south direction. An attempt to partially remedy the situation by building the Ob-Yenisei Canal was not particularly successful. Only a railway could be a real solution to the region's transport problems.

The first railway projects in Siberia emerged after the completion of the Moscow-Saint Petersburg Railway in 1851.[7] One of the first was the Irkutsk–Chita project, proposed by the American entrepreneur Perry Collins and supported by Transport Minister Constantine Possiet with a view toward connecting Moscow to the Amur River, and consequently, to the Pacific Ocean. Siberia's governor, Nikolay Muravyov-Amursky, was anxious to advance the colonisation of the Russian Far East, but his plans could not materialise as long as the colonists had to import grain and other food from China and Korea.[8] It was on Muravyov's initiative that surveys for a railway in the Khabarovsk region were conducted.

Before 1880, the central government had virtually ignored these projects, because of the weakness of Siberian enterprises, a clumsy bureaucracy, and fear of financial risk. By 1880, there were a large number of rejected and upcoming applications for permission to construct railways to connect Siberia with the Pacific, but not Eastern Russia. This worried the government and made connecting Siberia with Central Russia a pressing concern. The design process lasted 10 years. Along with the route actually constructed, alternative projects were proposed:

- Southern route: via Kazakhstan, Barnaul, Abakan and Mongolia.

- Northern route: via Tyumen, Tobolsk, Tomsk, Yeniseysk and the modern Baikal Amur Mainline or even through Yakutsk.

- Railwaymen fought against suggestions to save funds, for example, by installing ferryboats instead of bridges over the rivers until traffic increased. The designers insisted and secured the decision to construct an uninterrupted railway.

- Unlike the rejected private projects that intended to connect the existing cities demanding transport, the Trans-Siberian did not have such a priority. Thus, to save money and avoid clashes with land owners, it was decided to lay the railway outside the existing cities. Tomsk was the largest city, and the most unfortunate, because the swampy banks of the Ob River near it were considered inappropriate for a bridge. The railway was laid 70 km (43 mi) to the south (instead crossing the Ob at Novonikolaevsk, later renamed Novosibirsk); just a dead-end branch line connected with Tomsk, depriving the city of the prospective transit railway traffic and trade.

Construction

In March 1890, the future Tsar Nicholas II personally inaugurated the construction of the Far East segment of the Trans-Siberian Railway during his stop at Vladivostok, after visiting Japan at the end of his journey around the world. Nicholas II made notes in his diary about his anticipation of travelling in the comfort of "the tsar's train" across the unspoiled wilderness of Siberia. The tsar's train was designed and built in St. Petersburg to serve as the main mobile office of the tsar and his staff for travelling across Russia..

Similar to the First Transcontinental Railroad in the US, Russian engineers started construction at both ends and worked towards the centre. From Vladivostok the railway was laid north along the right bank of the Ussuri River to Khabarovsk at theAmur River, becoming the Ussuri Railway.

In 1890, a bridge across the Ural River was built and the new railway entered Asia. The bridge across the Ob River was built in 1898 and the small city of Novonikolaevsk, founded in 1883, grew into the large Siberian city of Novosibirsk. In 1898 the first train reached Irkutsk and the shores of Lake Baikal about 60 kilometres (37 miles) east of the city. The railway ran on to the east, across the Shilka and Amur rivers and soon reached Khabarovsk. The Vladivostok to Khabarovsk section was built slightly earlier, in 1897.

Russian soldiers, as well as convict labourers from Sakhalin and other places were used for building the railway.

Lake Baikal is more than 640 kilometres (400 miles) long and more than 1,600 metres (5,200 feet) deep. Until the Circum-Baikal Railway was built the line ended on either side of the lake. The ice-breaking train ferry SS Baikal built in 1897 and smaller ferry SS Angara built in about 1900, made the four-hour crossing to link the two railheads.[9][10] The Russian admiral and explorer Stepan Makarov (1849–1904) designed Baikal and Angara but they were built in Newcastle upon Tyne, England, by Armstrong Whitworth. They were "knock down" vessels; that is, each ship was bolted together in England, every part of the ship was marked with a number, the ship was disassembled into many hundreds of parts and transported in kit form to Listvyanka where a shipyard was built especially to reassemble them.[10] Their boilers, engines and some other components were built in Saint Petersburg[10] and transported to Listvyanka to be installed. Baikal had 15 boilers, four funnels, and was 64 metres (210 ft) long. She could carry 24 railway coaches and one locomotive on her middle deck.[9][10] Angara was smaller, with two funnels.[9][10]

Completion of the Circum-Baikal Railway in 1904 bypassed the ferries, but from time to time the Circum-Baikal Railway suffered from derailments or rockfalls so both ships were held in reserve until 1916.[9][10] Baikal was burnt out and destroyed in the Russian Civil War[9][10] but Angara survives.[9] She has been restored and is permanently moored at Irkutsk where she serves as an office and a museum.[9]

In winter, sleighs were used to move passengers and cargo from one side of the lake to the other until the completion of the Lake Baikal spur along the southern edge of the lake.

With the Amur River Line north of the Chinese border being completed in 1916, there was a continuous railway from Petrograd to Vladivostok that remains to this day the world's longest railway line. Electrification of the line, begun in 1929 and completed in 2002, allowed a doubling of train weights to 6,000 tonnes.

The additional Chinese Eastern Railway was constructed as the Russo-Chinese part of the Trans-Siberian Railway, connecting Russia with China and providing a shorter route to Vladivostok. A Russian staff and administration based in Harbin operated it.

Effects[edit]

The Trans-Siberian Railway gave a positive boost to Siberian agriculture, facilitating substantial exports to central Russia and Europe. It influenced the territories it connected directly, as well as those connected to it by river transport. For instance, Altai Krai exported wheat to the railway via the Ob River.

As Siberian agriculture began, from around 1869, to export cheap grain towards the West, agriculture in Central Russia was still under economic pressure after the end of serfdom, which was formally abolished in 1861. Thus, to defend the central territory and to prevent possible social destabilisation, in 1896 the government introduced the Chelyabinsk tariff break (Челябинский тарифный перелом), a tariff barrier for grain passing through Chelyabinsk, and a similar barrier in Manchuria. This measure changed the nature of export: mills emerged to create bread from grain in Altai Krai, Novosibirsk and Tomsk, and many farms switched to cornproduction. From 1896 until 1913 Siberia exported on average 501,932 tonnes (30,643,000 pood) of bread (grain, flour) annually.[11]

The Trans-Siberian Railway also brought with it millions of peasant-migrants from the Western regions of Russia and Ukraine.[12] Between 1906 and 1914, the peak migration years, about 4 million peasants arrived in Siberia.[13]

The railway was instantly filled to its capacity with local traffic, mostly wheat. Despite the low speed and low possible weights of trains, the railway fulfilled its promised role as a transit route between Europe and East Asia. During the Russo-Japanese War, the military traffic to the east almost disrupted the flow of civil freight.

War and revolution[edit]

In the Russo-Japanese War (1904–05), the Trans-Siberian Railway was seen as one of the reasons Russia lost the war. The track was a single track and as such could only allow train travel in one direction. This caused significant strategic and supply difficulties for the Russians, as they could not move resources to and from the front as quickly as would be necessary, as a goods train carrying supplies, men and ammunition coming from west to east would have to wait in the sidings, whilst troops and injured personnel in a troop train travelling from east to west went along the line. Thus the Japanese were quickly able to advance whilst the Russians were awaiting necessary troops and supplies. After the Russian Revolution of 1917, the railway served as the vital line of communication for the Czechoslovak Legion and the allied armies that landed troops at Vladivostok during the Siberian Intervention of the Russian Civil War. These forces supported the White Russiangovernment of Admiral Alexander Kolchak, based in Omsk, and White Russian soldiers fighting the Bolsheviks on the Ural front. The intervention was weakened, and ultimately defeated, by partisan fighters who blew up bridges and sections of track, particularly in the volatile region between Krasnoyarsk and Chita.[14][15][16]

The Trans-Siberian Railway also played a very direct role during parts of Russia's history, with the Czechoslovak Legion using heavily armed and armoured trains to control large amounts of the railway (and of Russia itself) during the Russian Civil War at the end of World War I.[17] As one of the few organised fighting forces left in the aftermath of the imperial collapse, and before the Red Army took control, the Czechs and Slovaks were able to use their organisation and the resources of the railway to establish a temporary zone of control before eventually continuing onwards towards Vladivostok, from where they emigrated back to Czechoslovakia through Vancouver in Canada, through Canada to Europe or the Panama Canal to Europe also through Japan, Hong Kong, Singapore, Port Said and Triest.

World War II[edit]

Main article: Pacific Route

During World War II, the Trans-Siberian Railway played an important role in the supply of the powers fighting in Europe.

During the first two years of the war, Germany's merchant shipping was interdicted by the Western Allies, the railway served as the essential link between Germany and Japan. One commodity particularly essential for the German war effort was natural rubber, which Japan was able to source from South-East Asia (in particular,French Indochina). As of March 1941, 300 tonnes of natural rubber would, on average, traverse the Trans-Siberian Railway every day on its way to Germany. According to one analysis of the natural rubber supply chain, as of 22 March 1941, 5,800 tonnes of this essential material were transiting on the Soviet railway network between the borders of Manchukuo and the Third Reich, 2,000 tonnes were transiting Manchukuo, 4,000 tonnes were sitting in Dairen, 3,800 tonnes were in Japan, and 5,700 tonnes, on the way from South-East Asia to Japan.[18]

During this time, a small number of German Jews and anti-Nazis used the Trans-Siberian to escape Europe, including the mathematician Kurt Gödel and the mother of the actor Heinz Bernard[19] Several thousand Jewish refugees were able to make this trip thanks to the Japanese visas issued by the Japanese consul in Kaunas,Chiune Sugihara.

The situation reversed after 22 June 1941. By invading the Soviet Union, Germany cut off its only reliable trade route to Japan (they had to use submarine blockade runners from that point on). On the other hand, the USSR became the recipient of lend lease supplies from the US. Even though Japan went to war with the US, it was anxious to preserve good relations with the USSR and, despite German complaints, usually allowed Soviet ships to sail between the US and Russia's Pacific ports unmolested[20] This contrasted with Germany and Britain's behaviour, whose navies would destroy or capture neutrals' ships sailing to their respective adversaries. As a result, the Pacific Route – involving crossing the northern Pacific Ocean and the Trans-Siberian Railway – became the safest connection between the US and the USSR. Accordingly, it accounted for as much freight as the two other routes (North Atlantic–Arctic and Iranian) combined.

The railway also played an important role in the evacuation of Soviet industries from European Russia to Siberia in 1941–42, and in the repositioning of Soviet troops from Germany to the Japanese front in preparation to the Soviet–Japanese War of August 1945.

Similar to the First Transcontinental Railroad in the US, Russian engineers started construction at both ends and worked towards the centre. From Vladivostok the railway was laid north along the right bank of the Ussuri River to Khabarovsk at theAmur River, becoming the Ussuri Railway.

In 1890, a bridge across the Ural River was built and the new railway entered Asia. The bridge across the Ob River was built in 1898 and the small city of Novonikolaevsk, founded in 1883, grew into the large Siberian city of Novosibirsk. In 1898 the first train reached Irkutsk and the shores of Lake Baikal about 60 kilometres (37 miles) east of the city. The railway ran on to the east, across the Shilka and Amur rivers and soon reached Khabarovsk. The Vladivostok to Khabarovsk section was built slightly earlier, in 1897.

Russian soldiers, as well as convict labourers from Sakhalin and other places were used for building the railway.

Lake Baikal is more than 640 kilometres (400 miles) long and more than 1,600 metres (5,200 feet) deep. Until the Circum-Baikal Railway was built the line ended on either side of the lake. The ice-breaking train ferry SS Baikal built in 1897 and smaller ferry SS Angara built in about 1900, made the four-hour crossing to link the two railheads.[9][10] The Russian admiral and explorer Stepan Makarov (1849–1904) designed Baikal and Angara but they were built in Newcastle upon Tyne, England, by Armstrong Whitworth. They were "knock down" vessels; that is, each ship was bolted together in England, every part of the ship was marked with a number, the ship was disassembled into many hundreds of parts and transported in kit form to Listvyanka where a shipyard was built especially to reassemble them.[10] Their boilers, engines and some other components were built in Saint Petersburg[10] and transported to Listvyanka to be installed. Baikal had 15 boilers, four funnels, and was 64 metres (210 ft) long. She could carry 24 railway coaches and one locomotive on her middle deck.[9][10] Angara was smaller, with two funnels.[9][10]

Completion of the Circum-Baikal Railway in 1904 bypassed the ferries, but from time to time the Circum-Baikal Railway suffered from derailments or rockfalls so both ships were held in reserve until 1916.[9][10] Baikal was burnt out and destroyed in the Russian Civil War[9][10] but Angara survives.[9] She has been restored and is permanently moored at Irkutsk where she serves as an office and a museum.[9]

In winter, sleighs were used to move passengers and cargo from one side of the lake to the other until the completion of the Lake Baikal spur along the southern edge of the lake.

With the Amur River Line north of the Chinese border being completed in 1916, there was a continuous railway from Petrograd to Vladivostok that remains to this day the world's longest railway line. Electrification of the line, begun in 1929 and completed in 2002, allowed a doubling of train weights to 6,000 tonnes.

The additional Chinese Eastern Railway was constructed as the Russo-Chinese part of the Trans-Siberian Railway, connecting Russia with China and providing a shorter route to Vladivostok. A Russian staff and administration based in Harbin operated it.

Effects[edit]

The Trans-Siberian Railway gave a positive boost to Siberian agriculture, facilitating substantial exports to central Russia and Europe. It influenced the territories it connected directly, as well as those connected to it by river transport. For instance, Altai Krai exported wheat to the railway via the Ob River.

As Siberian agriculture began, from around 1869, to export cheap grain towards the West, agriculture in Central Russia was still under economic pressure after the end of serfdom, which was formally abolished in 1861. Thus, to defend the central territory and to prevent possible social destabilisation, in 1896 the government introduced the Chelyabinsk tariff break (Челябинский тарифный перелом), a tariff barrier for grain passing through Chelyabinsk, and a similar barrier in Manchuria. This measure changed the nature of export: mills emerged to create bread from grain in Altai Krai, Novosibirsk and Tomsk, and many farms switched to cornproduction. From 1896 until 1913 Siberia exported on average 501,932 tonnes (30,643,000 pood) of bread (grain, flour) annually.[11]

The Trans-Siberian Railway also brought with it millions of peasant-migrants from the Western regions of Russia and Ukraine.[12] Between 1906 and 1914, the peak migration years, about 4 million peasants arrived in Siberia.[13]

The railway was instantly filled to its capacity with local traffic, mostly wheat. Despite the low speed and low possible weights of trains, the railway fulfilled its promised role as a transit route between Europe and East Asia. During the Russo-Japanese War, the military traffic to the east almost disrupted the flow of civil freight.

War and revolution[edit]

In the Russo-Japanese War (1904–05), the Trans-Siberian Railway was seen as one of the reasons Russia lost the war. The track was a single track and as such could only allow train travel in one direction. This caused significant strategic and supply difficulties for the Russians, as they could not move resources to and from the front as quickly as would be necessary, as a goods train carrying supplies, men and ammunition coming from west to east would have to wait in the sidings, whilst troops and injured personnel in a troop train travelling from east to west went along the line. Thus the Japanese were quickly able to advance whilst the Russians were awaiting necessary troops and supplies. After the Russian Revolution of 1917, the railway served as the vital line of communication for the Czechoslovak Legion and the allied armies that landed troops at Vladivostok during the Siberian Intervention of the Russian Civil War. These forces supported the White Russiangovernment of Admiral Alexander Kolchak, based in Omsk, and White Russian soldiers fighting the Bolsheviks on the Ural front. The intervention was weakened, and ultimately defeated, by partisan fighters who blew up bridges and sections of track, particularly in the volatile region between Krasnoyarsk and Chita.[14][15][16]

The Trans-Siberian Railway also played a very direct role during parts of Russia's history, with the Czechoslovak Legion using heavily armed and armoured trains to control large amounts of the railway (and of Russia itself) during the Russian Civil War at the end of World War I.[17] As one of the few organised fighting forces left in the aftermath of the imperial collapse, and before the Red Army took control, the Czechs and Slovaks were able to use their organisation and the resources of the railway to establish a temporary zone of control before eventually continuing onwards towards Vladivostok, from where they emigrated back to Czechoslovakia through Vancouver in Canada, through Canada to Europe or the Panama Canal to Europe also through Japan, Hong Kong, Singapore, Port Said and Triest.

World War II[edit]

Main article: Pacific Route

During World War II, the Trans-Siberian Railway played an important role in the supply of the powers fighting in Europe.

During the first two years of the war, Germany's merchant shipping was interdicted by the Western Allies, the railway served as the essential link between Germany and Japan. One commodity particularly essential for the German war effort was natural rubber, which Japan was able to source from South-East Asia (in particular,French Indochina). As of March 1941, 300 tonnes of natural rubber would, on average, traverse the Trans-Siberian Railway every day on its way to Germany. According to one analysis of the natural rubber supply chain, as of 22 March 1941, 5,800 tonnes of this essential material were transiting on the Soviet railway network between the borders of Manchukuo and the Third Reich, 2,000 tonnes were transiting Manchukuo, 4,000 tonnes were sitting in Dairen, 3,800 tonnes were in Japan, and 5,700 tonnes, on the way from South-East Asia to Japan.[18]

During this time, a small number of German Jews and anti-Nazis used the Trans-Siberian to escape Europe, including the mathematician Kurt Gödel and the mother of the actor Heinz Bernard[19] Several thousand Jewish refugees were able to make this trip thanks to the Japanese visas issued by the Japanese consul in Kaunas,Chiune Sugihara.

The situation reversed after 22 June 1941. By invading the Soviet Union, Germany cut off its only reliable trade route to Japan (they had to use submarine blockade runners from that point on). On the other hand, the USSR became the recipient of lend lease supplies from the US. Even though Japan went to war with the US, it was anxious to preserve good relations with the USSR and, despite German complaints, usually allowed Soviet ships to sail between the US and Russia's Pacific ports unmolested[20] This contrasted with Germany and Britain's behaviour, whose navies would destroy or capture neutrals' ships sailing to their respective adversaries. As a result, the Pacific Route – involving crossing the northern Pacific Ocean and the Trans-Siberian Railway – became the safest connection between the US and the USSR. Accordingly, it accounted for as much freight as the two other routes (North Atlantic–Arctic and Iranian) combined.

The railway also played an important role in the evacuation of Soviet industries from European Russia to Siberia in 1941–42, and in the repositioning of Soviet troops from Germany to the Japanese front in preparation to the Soviet–Japanese War of August 1945.

The railway today

The Trans-Siberian line remains the most important transport link within Russia; around 30% of Russian exports travel on the line. While it attracts many foreign tourists, it gets most of its use from domestic passengers.

The Trans-Siberian is a vital link to the Russian Far East.

Today the Trans-Siberian Railway carries about 200,000 containers per year to Europe. Russian Railways intends to at least double the volume of container traffic on the Trans-Siberian and is developing a fleet of specialised cars and increasing terminal capacity at the ports by a factor of 3 - 4. By 2010, the volume of traffic between Russia and China could reach 60 million tons (54 million tonnes), most of which will go by the Trans-Siberian.[21]

With perfect coordination of the participating countries' railway authorities, a trainload of containers can be taken from Beijing to Hamburg, via the Trans-Mongolian and Trans-Siberian lines in as little as 15 days, but typical cargo travel times are usually significantly longer[22]—e.g., typical cargo travel time from Japan to major destinations in European Russia was reported as around 25 days.[23]

According to a 2009 report, the best travel times for cargo block trains from Russia's Pacific ports to the western border (of Russia, or perhaps of Belarus) were around 12 days, with trains making around 900 km (559 mi) per day, at a maximum operating speed of 80 km/h (50 mph). However, in early 2009 Russian Railways announced an ambitious "Trans-Siberian in Seven Days" programme; according to this plan, $11 billion will be invested over the next five years to make it possible for goods traffic to cover the same 9,000 km (5,592 mi) distance in just seven days. The plan will involve increasing the cargo trains' speed to 90 km/h (56 mph) in 2010–12, and, at least on some sections, to 100 km/h (62 mph) by 2015. At these speeds, goods trains will be able to cover 1,500 km (932 mi) per day.[24]

Developments in shipping

Main article: Trans-Eurasia Logistics

On 11 January 2008, China, Mongolia, Russia, Belarus, Poland and Germany agreed to collaborate on a cargo train service between Beijing and Hamburg

The railway can typically deliver containers in ⅓ to ½ of the time of a sea voyage, and in late 2009 announced a 20% reduction in its container shipping rates. With its 2009 rate schedule, the TSR will transport a forty-foot container to Poland from Yokohama for $2,820, or from Pusan for $2,154.[26]

One of the complicating factors related to such ventures is the fact that the CIS states' broad railway gauge is incompatible with China and Western and Central Europe's standard gauge. Therefore, a train travelling from China to Western Europe would encounter gauge breaks twice: at the Chinese-Mongolian or the Chinese-Russian frontier and at the Ukrainian or the Belorussian border with Central European countries.

The Trans-Siberian is a vital link to the Russian Far East.

Today the Trans-Siberian Railway carries about 200,000 containers per year to Europe. Russian Railways intends to at least double the volume of container traffic on the Trans-Siberian and is developing a fleet of specialised cars and increasing terminal capacity at the ports by a factor of 3 - 4. By 2010, the volume of traffic between Russia and China could reach 60 million tons (54 million tonnes), most of which will go by the Trans-Siberian.[21]

With perfect coordination of the participating countries' railway authorities, a trainload of containers can be taken from Beijing to Hamburg, via the Trans-Mongolian and Trans-Siberian lines in as little as 15 days, but typical cargo travel times are usually significantly longer[22]—e.g., typical cargo travel time from Japan to major destinations in European Russia was reported as around 25 days.[23]

According to a 2009 report, the best travel times for cargo block trains from Russia's Pacific ports to the western border (of Russia, or perhaps of Belarus) were around 12 days, with trains making around 900 km (559 mi) per day, at a maximum operating speed of 80 km/h (50 mph). However, in early 2009 Russian Railways announced an ambitious "Trans-Siberian in Seven Days" programme; according to this plan, $11 billion will be invested over the next five years to make it possible for goods traffic to cover the same 9,000 km (5,592 mi) distance in just seven days. The plan will involve increasing the cargo trains' speed to 90 km/h (56 mph) in 2010–12, and, at least on some sections, to 100 km/h (62 mph) by 2015. At these speeds, goods trains will be able to cover 1,500 km (932 mi) per day.[24]

Developments in shipping

Main article: Trans-Eurasia Logistics

On 11 January 2008, China, Mongolia, Russia, Belarus, Poland and Germany agreed to collaborate on a cargo train service between Beijing and Hamburg

The railway can typically deliver containers in ⅓ to ½ of the time of a sea voyage, and in late 2009 announced a 20% reduction in its container shipping rates. With its 2009 rate schedule, the TSR will transport a forty-foot container to Poland from Yokohama for $2,820, or from Pusan for $2,154.[26]